Introduction To Silicone Release Coating

Silicone release coating refers to a specialized layer applied to substrates such as paper, film, or

textiles to impart non-stick properties. Composed primarily of silicone polymers, these coatings

are cured to form a smooth, inert surface that facilitates easy release of adhesives, tapes, labels,

and other materials during manufacturing or application processes. The primary function of

silicone release coatings is to prevent bonding between the substrate and adhesive materials,

ensuring clean and efficient transfer without residue or damage. This capability is crucial in

industries such as packaging, where precise and reliable release properties are essential for

maintaining production efficiency and product quality.

Silicone release coatings are valued for their versatility, offering options for different release force

requirements, environmental resistances, and compatibility with various substrates. They play a

pivotal role in enhancing product performance, reducing waste, and optimizing manufacturing

processes across a wide range of industrial and consumer applications

Overview Of Silicone Release Coatings

Wide adaptability to various substrates.

High adaptability to a broad range of temperatures.

Excellent compatibility with various adhesives.

Minimal migration of the cured coating.

Flexible mixing formula, with peel force adjustable between 5-200g/25mm.

Suitable for high-speed coating processes.

Safe and non-toxic when cured.

Reliable performance across diverse application conditions.

Most Common Applications

Self-adhesive labels

- Labels of general consumer goods such as food, beverage and cosmetics

- Price label, barcode label, smart label

- Security label, anti-counterfeit label

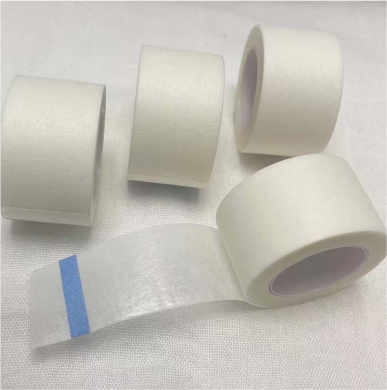

Pressure-sensitive Speciality tapes

- Sanitary pads for women, diapers

- Plaster patch, medical adhesive tape

Health Care Product

- Automobile decoration

- Advertising board, advertising stickers

- Building decoration and protection

Advertising and decoration

- Automobile decoration

- Advertising board, advertising stickers

- Building decoration and protection

Industrial and other consumer goods

- Waterproof rolls (asphalt)

- Courier bags, envelopes and stamps

- Insulating stop, composite material

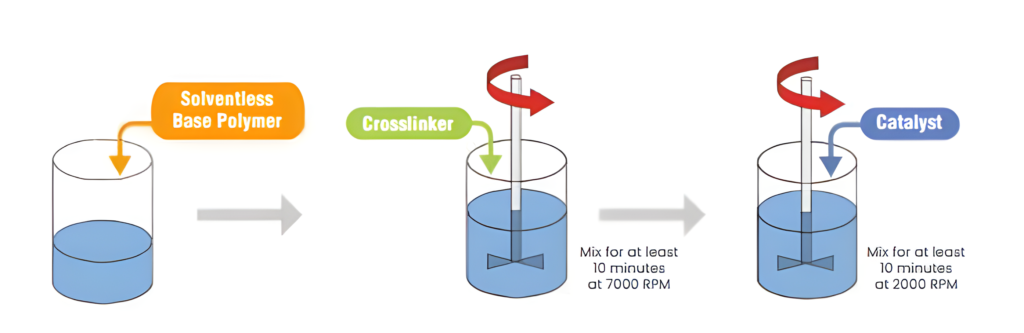

Instructions For Use

The standard mixing ratio for solvent less silicon base polymer/crosslinker/catalyst :

1000/32/8. First, combine the base polymer and cross linker then mix for at least 10 minutes to a

uniform consistency. Next, add the catalyst and again mix for at least 10 minutes until uniform

consistency. Once all liquids are evenly mixed, the compound can be used immediately.